The rise of Industry 4.0 has transformed how businesses approach operational technology (OT) and the Internet of Things (IoT). Among the most promising innovations is the Digital Twin, a real-time virtual representation of physical assets, processes, or systems. In OT/IoT environments, where SCADA (Supervisory Control and Data Acquisition) has traditionally played a vital role in real-time monitoring and control, Digital Twin technology emerges not as a replacement, but as a powerful complementary layer that enhances forecasting, simulation, and decision-making capabilities.

What is a Digital Twin?

A Digital Twin is a digital replica of a physical object or process that uses real-time data from sensors and control systems to simulate and reflect the current state, behavior, and performance of the real-world entity. This virtual model evolves alongside its physical counterpart, enabling continuous analysis, simulation, and optimization.

Understanding SCADA in OT Systems

SCADA systems are essential in OT environments. They gather real-time data from field devices, enable control through PLCs (Programmable Logic Controllers), and provide a human-machine interface (HMI) for monitoring operations. SCADA's primary function is to ensure reliable, efficient control and real-time operational visibility.

Digital Twin and SCADA: A Complementary Relationship

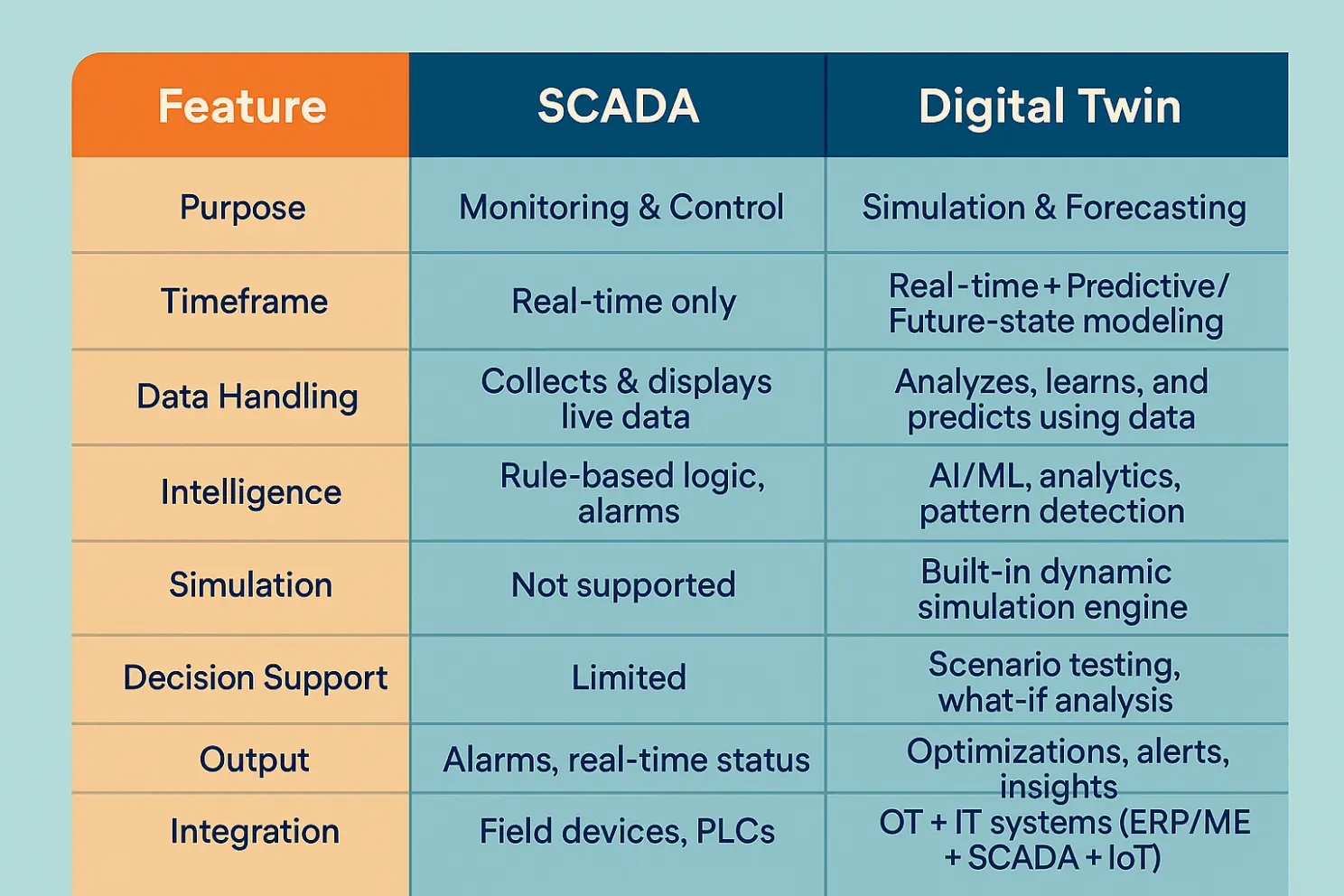

Rather than displacing SCADA, Digital Twins add a higher level of intelligence and predictive capability. Here’s how they complement each other:

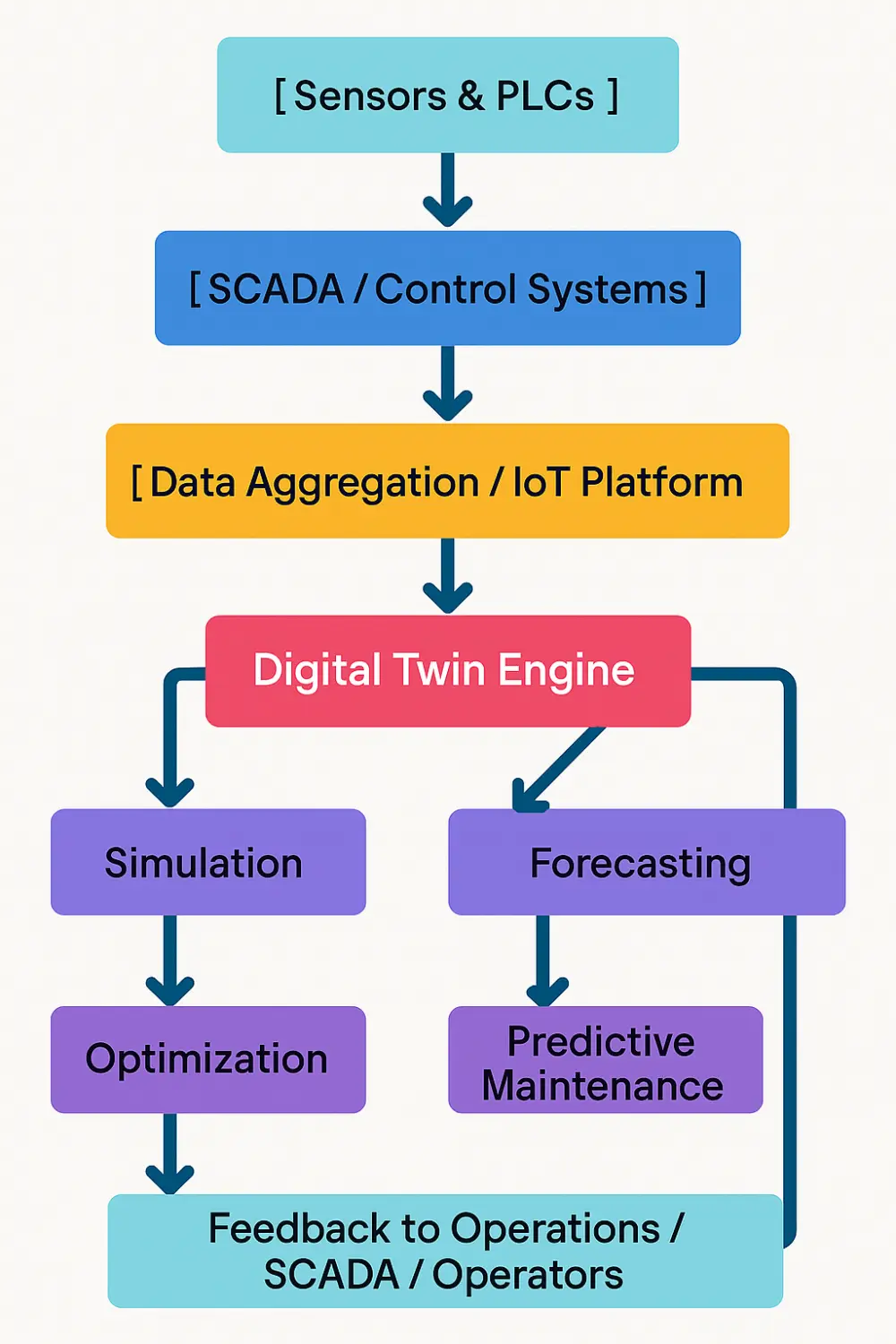

- Real-Time Data Sharing: SCADA systems collect data from sensors and devices. This data is fed into the Digital Twin, allowing the twin to maintain an accurate virtual model of the system.

- Simulation and Forecasting: While SCADA systems report the current state, Digital Twins simulate potential future states. This enables predictive maintenance, performance optimization, and risk assessment.

- Advanced Analytics: SCADA systems often lack sophisticated analytics. Digital Twins can apply machine learning, AI, and statistical modeling to the data, offering insights into trends and anomalies.

- Decision Support: With simulation capabilities, Digital Twins provide operators with foresight into the outcomes of various decisions, such as process changes or maintenance schedules, without disrupting live operations.

- IT/OT Integration: Digital Twins bridge the gap between IT and OT by integrating enterprise systems (like ERP or MES) with real-time operational data from SCADA.

Advantages of Integrating Digital Twins in OT/IoT Architecture

- Enhanced Operational Efficiency: By simulating different process conditions, operators can identify optimal operating parameters and reduce energy consumption or waste.

- Predictive Maintenance: Digital Twins analyze sensor data to predict failures before they happen, reducing unplanned downtime.

- Process Optimization: Simulating process flows helps in identifying inefficiencies and bottlenecks, enabling continuous improvement.

- Safety and Risk Management: Risk scenarios can be virtually tested, helping to avoid hazards in the real system.

- Remote Monitoring and Control: Digital Twins allow remote teams to interact with a virtual model, improving accessibility and response time.

- Training and Simulation: Virtual environments based on Digital Twins can be used for staff training and testing new control strategies.

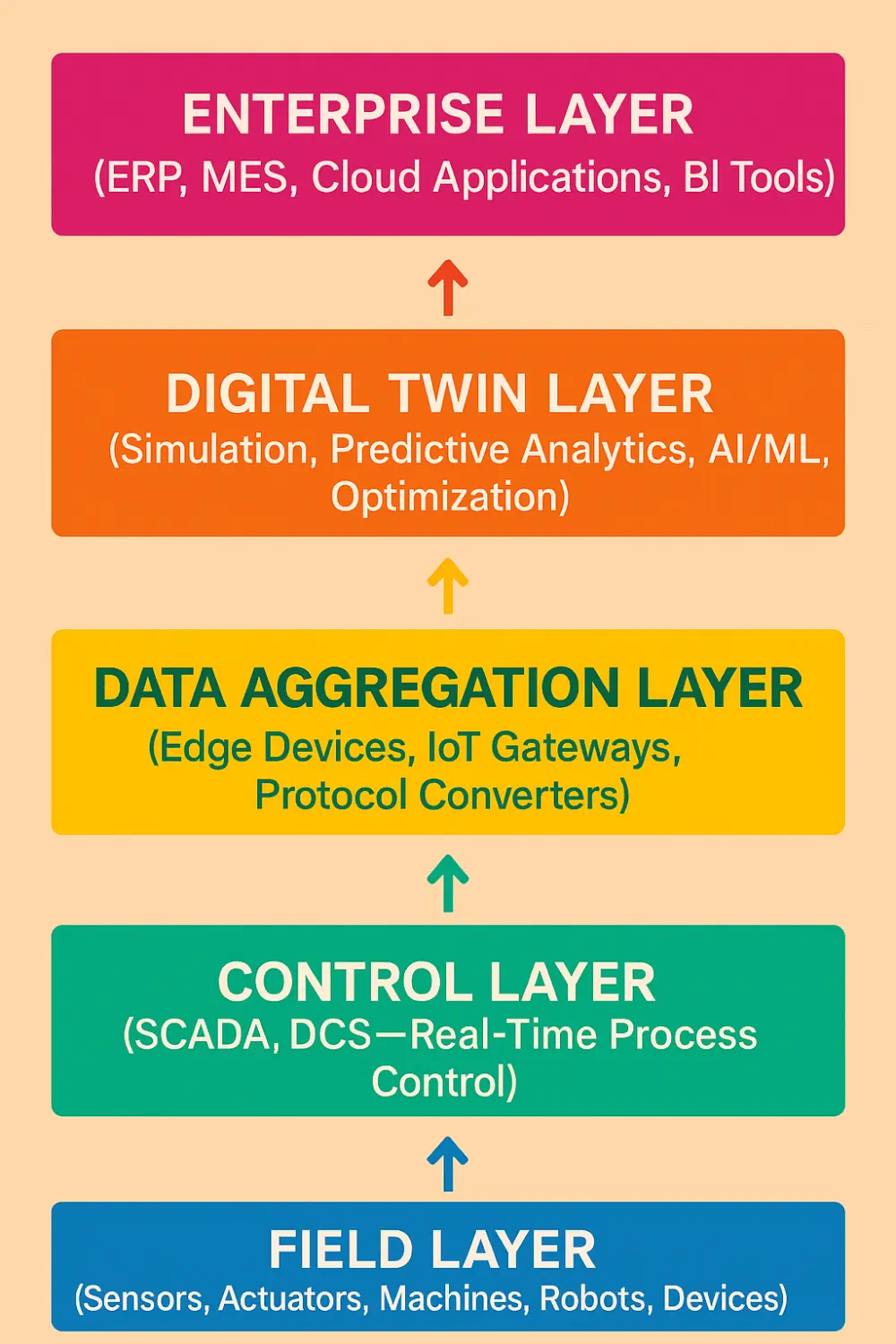

Digital Twin in OT/IoT Architecture

Field Layer: IoT sensors, actuators, PLCs collect and execute physical data.

Control Layer: SCADA/DCS systems manage process control and real-time monitoring.

Data Aggregation Layer: IoT platforms, gateways, or edge devices aggregate and preprocess data.

Digital Twin Layer:

Receives data from control and aggregation layers.

Simulates and models processes in real-time.

Applies AI/ML algorithms for forecasting and decision-making.

Enterprise Layer: ERP, MES, and other business systems interact with insights from the digital twin for planning and logistics.

Process and Simulation Example

Consider a manufacturing plant with a complex assembly line. Sensors report data such as motor speed, conveyor status, temperature, and vibration to SCADA, which controls the process in real time. A Digital Twin of this line uses the same data to:

- Simulate the impact of speed changes on overall production.

- Predict wear and tear on specific components.

- Optimize workflow and reduce idle times.

- Test new product designs or configurations virtually.

Operators can visualize these simulations via dashboards, make informed adjustments, and validate strategies before applying them in the real world.